The basic structure of an optoisolator!

An optoisolator is an electronic device that transmits electrical energy from one circuit to another via a short optical transmission path while providing electrical isolation between the two circuits. Opto-isolators couple high voltage from one side of a circuit to the other without any direct electrical contact.

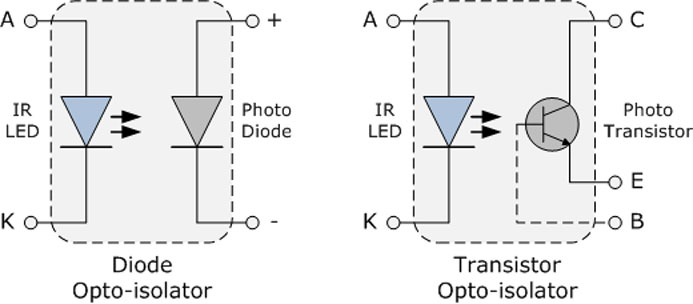

These devices use light-emitting diodes to convert electrical energy into a beam of light, which is then directed to a light sensor (such as a photodiode or phototransistor), which converts the light energy back into electrical energy. This isolates the two circuits, prevents voltage spikes, and reduces noise and interference associated with communication connections.

Opto-isolators are widely used in power supplies, control and monitoring systems, communications and other systems to safely connect one circuit section to another while preventing direct contact and high voltage from affecting the low voltage side.

The basic structure of an optoisolator!

A typical optoisolator consists of a near infrared light emitting diode LED, a photodiode, an optical sensor such as a phototransistor or a phototransistor, a closed channel and a power supply. These two components are typically encapsulated in an opaque housing to prevent external light from interfering with the emitted beam, and are packaged in a package similar to an IC or transistor with additional leads.

There are different types of optoisolators based on the optical response device and configuration. Two common types are

Photodiodes: use LEDs as light sources and silicon photodiodes as light sensors

Phototransistor: used as a phototransistor as a light sensor

Basic operation of an opto-isolator!

A voltage from the primary circuit is applied to the power supply to produce a near-infrared light beam which passes through the closed channel until it hits the phototransistor which converts light energy into electrical energy. Since the LED and the phototransistor or photodiode are separate and have no direct electrical connection, the device provides isolation of the two parts of the circuit while being able to transfer electrical energy from one part to the other.

Once light from the LED hits the phototransistor, it begins to conduct electricity depending on the state and duration of the light. Opto-isolators are packaged in a variety of styles, including cylindrical, rectangular or other special configurations. These devices are designed to isolate higher voltages than the optocoupler SMD and DIP packages can handle.

Optopcouplers and optoisolators are sometimes used interchangeably; however, optocouplers handle voltages up to approximately 5000V, while optoisolators handle voltages in excess of 5000V.

Parameters and specifications of opto-isolators:

Current Transfer Ratio, CTR: Ratio between LED and sensor current

Isolation voltage: Maximum guaranteed voltage between the LED and the optical sensor

Linearity

Maximum voltage of the output device

Input current

Bandwidth

Factors affecting the operation of the optoisolator

The breakdown potential outside the optoisolator depends on factors such as temperature, humidity, distance, air pressure, type and concentration of contaminants in the air. Therefore, these devices are affected by humidity, especially at higher voltages of about 50.000 DC. High humidity in the air can lead to arcing around the isolator or on the surface of the circuit board, resulting in possible short circuits in the conductive path and around the opto-isolator.

The advantages of opto-isolators include

Provide electrical and physical isolation of both parts of the circuit, thus ensuring safety

Minimizes noise sensitivity and EMI, and reduces interference such as electrical interference

Relatively small and inexpensive

Ability to limit the voltage between multiple circuits

Provides isolation

Disadvantages of optoisolators

Have limitations and cannot be used in certain electrical systems

Subject to humidity, air pollution and air pressure, each if which can cause arcing and interference with isolation Requires these devices to be used in climate-controlled areas.

Applications of optoisolators

Optoisolators are used in a variety of optical applications, including power supplies that provide isolation, the recording industry that reduces interference, and computer systems that transmit data. Applications include

Power feedback systems

Medical, industrial, applications

Isolation of ground loop currents

High voltage level conversion

Signal isolation

Power and noise isolation

At this stage, the main products such as optocoupler relays and optocouplers are used in: Power storage systems. Smart meters. Automatic detection equipment. Telecommunication equipment. Measuring instruments. Medical equipment. Communication equipment. PC terminal. Security monitoring. O/A equipment. PLC controller. I/O control board, etc. Relying on the comprehensive design technology and chip manufacturing technology advantages of optical semiconductor, we expect to plow deeper in the field of optoelectronic control with broad development prospects, gradually enhance the technical added value of our products and expand the product line with higher technical content.